Sheet Metal Machinery Topics21. Jul. 2023 Independent tapping device is deeply favored by the customer. This 30-ton punch M3048TG with tapping device will be sent to India soon. We believe that this equipment can greatly improve the customer’s production efficiency & accuracy and fully realize the expected effect!

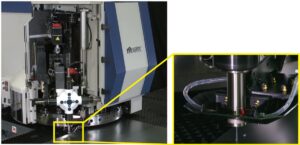

In recent years, under the situation of outflow of labor power and sharp rise in labor costs in the sheet metal processing industry, the demand for automation and process integration is increasing. Murata Machinery's composite processing machines that integrate multiple processing technologies such as punching, cutting, forming, tapping, and deburring are also widely favored by customers. This time, when discussing the punch + tapping compound machine with the customer who process thin, medium and thicker sheets, they spoke highly of our unique independent tapping device. The following will lead everyone to learn more about some Murata machinery tapping devices.

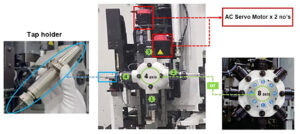

High quality processing is guaranteed for various thickness sheets.By using two servo motors to control, the rotation and feed can be synchronized by NC controller, and the processing can be performed at the most suitable speed depending on different thicknesses and materials. In addition, it is equipped with a chip suction device, which vacuums and removes chips from below while processing to prevent chips from bouncing back to the surface of the sheet.

Simple and easy-to-use structure can greatly reduce the burden of preparation workGenerally, rolling tapping taps aren't universal and depending on different thicknesses and material type, different taps might need to be prepared that are specified by the manufacturer. Therefore, for customers who process a variety of materials, they need to change taps very often and the burden before work is heavy. On the contrary, Muratec's taps have high versatility and basically don't need to replace them. It doesn't occupy the turret station, the structure is simple and easy to replace the tap. Also it's easy to operate with the touch screen operation panel, which greatly reduces the preparation before work and improves the operation efficiency.

Low running costAs mentioned above, the rolling tapping requires the use of special taps specified by the equipment manufacturer and various special taps need to be prepared according to different thicknesses and materials, therefor the operating cost is relatively high. Murata Machinery's tapping device adopts a special tapping machine structure to solve such problems. It fully meets the tapping processing with our punching press or laser cutting machines. The taps are common standard taps you can buy on Indian market, which truly achieves low cost and high operation.  |