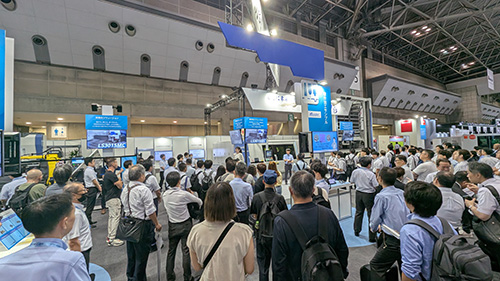

News17. Jul. 2025 Muratec Sheet Metal Division is participating in MF-TOKYO 2025.

Fiber Laser Combination Machine [LS3015MC] A versatile combination machine designed for medium‑thick plate processing, integrating both laser cutting and punching. It delivers high‑speed, high‑quality performance with a fiber laser, capable of cutting, drilling, tapping, deep counter-bore, and large countersink up to 16 mm sheet thickness. Many visitors gathered for the demonstration, as combination machines with this level of capability have been extremely rare so far.

Bending Robot System [MBRS – Muratec Bending Robot System] This automated bending system accommodates variable‑mix, variable‑volume production, integrating a press brake, bending robot, automatic tooling changer, and robot‑dedicated CAM into a single package. This enables bending operations, which were previously performed manually, to be carried out more easily, more accurately, and more safely.

Connected Operation Support System “ProcessNet Portal” This system connects customers and Muratec through the cloud, securely uploading machine operation data such as processing progress, alarm history, and maintenance status. Through the PNP site, you can monitor the operating status anytime, anywhere.

In the same booth, Murata Tools is also exhibiting its new product, the “Disk-Type Deburring Machine DB1000F.” In addition, Muratec CCS is exhibiting the “Slat Dross Cleaner,” a dross removal tool for laser processing machines.

|